Extinguishers: A Reliable Extinguisher Gauge is Critical for Safety.

All extinguisher gauges are of the Bourdon tube design most often called a “Bourdon tube gauge”. This pressure-measuring device was named after, and patented by, French engineer, Eugene Bourdon around 1849. It is a very simple and fairly inexpensive mechanical device. The pressure sensing component is a tiny, flattened metal tube coiled within the gauge. One end of the tube is exposed to the pressure within the cylinder. The other end is sealed and has a yellow pointer attached. The coiled tube straightens when pressure is applied, and the pointer indicates the relative pressure within the cylinder. The acceptable practice is to have a red face plate with a green area that indicates that the pressure is within the operable range to force full discharge of the agent. Here is what you need to know about these inexpensive but critical extinguisher components.

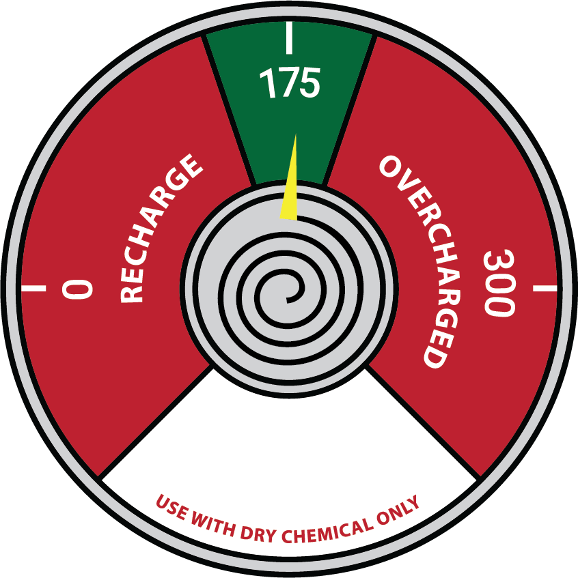

Fig: Bourbon Tube Gauge

A stored pressure fire extinguisher is the most common type of extinguisher. It has both the extinguishing agent and the pressurizing gas within the same container. You can easily identify a stored pressure dry chemical extinguisher because it has a pressure gauge installed on the valve. A stored pressure extinguisher is ready to use if it contains agent and is sufficiently pressurized. You can tell whether an extinguisher is empty or full of agent by lifting it. The extinguisher gauge, with a reading in the operable range, tells you the extinguisher has sufficient pressure to force the discharge of the agent.

The pressurization is provided by an expellant, such as pressurized air (water and new extinguishers), or an approved gas, such as nitrogen or argon. The agent cannot be discharged from the cylinder without this expellant. The indication that the extinguisher has been pressurized, and remains pressurized, is the pressure gauge installed in the valve of the extinguisher. The pressure gauge is an extremely critical component of an extinguisher and must be checked regularly (at least monthly, according to NFPA 10) to assure that the pressure indication remains in the operable range (green area) and the gauge is not damaged. Without sufficient pressure, some of the agent will remain in the extinguisher and not be released to extinguish a threatening fire. The worst case is when the extinguisher is unpressurized, and no agent is released. This could be disastrous in the event of a fire, resulting in injuries, fatalities, and property loss.

Although extinguisher gauges are pretty crude and simple mechanical devices, they are accurate enough for indicating extinguisher readiness. Manufacturers of these gauges match the red gauge face with the green area carefully to provide a fairly accurate indication of pressure and readiness. Although each gauge face has some corresponding pressure reading marks, most people only look to see whether the pointer is within the green area, meaning the extinguisher has the proper pressure that is in the “operable range” of the extinguisher. When the gauge needle is in the green zone, the extinguisher lever can be squeezed to open the extinguisher valve and the pressure within the extinguisher will satisfactorily force the discharge of agent onto the fire to extinguish it. If the yellow pointer is in the red zone, it either lacks sufficient pressure (discharged and in need of a recharge) or is over-pressurized. Both conditions require servicing by a qualified technician before returning the extinguisher to its mounting location.

An extinguisher gauge is relied upon to indicate that the unit is pressurized and ready to use in the event of a fire emergency. Using Brooks’ replacement gauges provide a reasonable assurance that the gauges will provide accurate readings and the extinguisher will be ready for use during a fire emergency.

Click Here to view a PDF version

© 2022 Brooks Equipment.

Disclaimer: The opinions expressed in the above Tech Series

article are the author’s only and provide limited information.

Although the information is believed to be reliable, Brooks

Equipment Company, LLC expressly disclaims any warranty with

respect to the information and any liability for errors or

omissions. The user of this article or the product(s) is

responsible for verifying the information’s accuracy from all

available sources, including the product manufacturer. The

authority having jurisdiction should be contacted for

code interpretations.